Replacing Legacy Instrumentation with Form/Fit/Function (FFF) InstrumentationFrom Test Connections Newsletter - June 2015

Military, aerospace and even commercial products require support equipment for production and maintenance. One important type of support equipment is functional Automated Test Equipment (ATE). When a dedicated test system fails and is not available, there is usually an immediate impact on the product it supports. It can be a monetary impact or even worse, readiness impact. Legacy ATE systems are being pushed into extended service, beyond the service years for which they were originally intended, and as they age, the downtime increases. Instrument obsolescence is one of the major reasons for test system down time. If a system resource fails, it must be repaired or replaced. If the instrument is no longer produced (i.e. obsolete), then other, less traditional remedies must be employed.

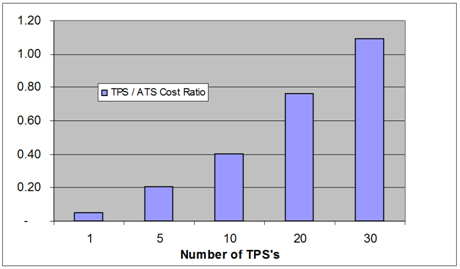

Preserving InvestmentOver a test system’s life span, significant costs can accrue. ATE costs start with the initial investment for designing, building and developing Test Program Sets (TPSs). However, after the initial cost of ATE deployment, test system costs will continue to accrue due to the on-going investment in test programs, fixtures, etc. And over time, the major investment component will become the test programs which increases exponentially, as the number of programs are added to a system.

Cost of TPS Relative to ATE Capital Cost Cost of TPS Relative to ATE Capital Cost

Additionally, as the ATE matures, maintenance costs will increase due to ageing and obsolescence issues. Consequently, to preserve the investment in the test system and associated test programs, identifying “drop – in” or form, fit, function replacement solutions for obsolescence issues can offer a cost-effective solution.

Replacement OptionsStockpiling Spares

Stockpiling of spare instruments is one way to mitigate system down time and maintenance issues. The spare instruments may be procured as part of the initial investment, during the ATE life span or as a life time buy when the notice of end of life is received. With the typical life span for commercial instrumentation being 5-7 years, but with test systems in use for 20 or more years, this strategy is routinely employed by test system maintainers. However; this is only a short-term solution, particularly when dealing with system life cycles of 20+ years since at some point, the spares will be depleted.

Ongoing Maintenance and Repair

On-going maintenance and repair of the obsolete instrument may be an option. However, the problem with this approach is the ever-increasing cost and time to repair as well as obtaining components which may become obsolete. Even if some systems are reserved for cannibalization, the source of instruments and parts will eventually be exhausted - resulting in a short-term solution at best.

Used Instruments

A tempting solution is to find an instrument replacement on the secondary market. Many test equipment distributors offer used instruments and depending on the age of the instrument (how long it has been out of production), there is a good chance of finding the instrument on the secondary market. However, even if the equipment is in pristine condition, this is still a short term solution to the long term problem of support and maintenance since eventually, this source will be exhausted.

TPS Migration / COTS Instrument with Adapter

A long-term solution can be the migration of the test program to a new, up-to-date test system.

However, this approach can be very expensive; especially if a large number of TPS’ are involved and particularly if new fixtures are also part of the conversion process. Consequently, the high cost associated with a complete test program re-host strategy usually precludes TPS migration to a new test platform. What is a more likely scenario is to selectively replace those instruments that are obsolete with a new COTS instrument which can offer comparable functionality and performance. However, software functionality will not be compatible, requiring a software driver wrapper or adapter. Identifying a COTS functional replacement should be done with care. The candidate instrument’s specification should be scrutinized closely to verify that all the features used in the ATE are compatible, all the levels and ranges are covered, and all required inputs and outputs exist. An important issue that must be addressed is the improved performance of the new instrument. Newer instruments will, in most cases, have much faster or better performance than the obsolete instrument which will typically lead to TPS failures. For example, if a DMM with a reading rate of 100 readings per second is being replaced by a new DMM with a reading rate of 1000 readings per second, it may be necessary to add delays to the test program.

In most cases the new instrument is not compatible with the legacy command set and translation/adaption is required. The translation should replicate the legacy instrument’s commands as well as the instrument’s response. Comprehensive functionality also needs to include any self-test functionality that the legacy instrument may have offered, since overall compatibility must address not only test program functionality, but also any system self-test functionality which may incorporate individual instrument self-test functionality. Instrument adaption can be accomplished in one of two ways:

- Software conversion layer or wrapper: With addition of a software wrapper to the instrument’s driver, the replacement instrument will be compatible with the legacy instrument’s commands and TPSs should be able to use the new instrument with virtually no changes. Of course once installed, the legacy instrument cannot be used any more. However, like all software development tasks, there is also some risk involved and in many cases, changes to the test program may be required, necessitating revalidation of the complete test program - incurring additional time and expense.

- Hardware adapter or Translation Module Adapter (TMA): A TMA is a stand-alone unit that connects between the system controller and the replacement instrument. The TMA has its own processor and uses two ports; one to communicate with the system controller and one to communicate with the replacement instrument. Special firmware needs to be developed to accept the legacy commands from the controller and translate them to the new instrument’ commands. Like its software counterpart, once a hardware adapter is implemented, TPSs should be able to use the new instrument with virtually no changes but unlike the software adapter, the legacy instrument can still be used simply by bypassing the TMA. Hardware adapters face similar obstacles as their software counterparts. There is some risk involved with firmware development and communication response time can create timing issues, necessitating test program revisions - requiring TPS revalidation.

Form, Fit Function (FFF) Instrument Replacement - A Superior SolutionFFF instrument replacement offers a superior solution for replacing out of production, legacy instrumentation. A modern, COTS instrument with an integral communication interface adapter offers a drop in replacement that is functionally, electrically, and mechanically equivalent to the legacy instrument, preserving the initial investment in the ATE and associated TPS’. Key features and benefits associated with an FFF solution include:

- Preservation of existing test programs. Great care is taken replicate the legacy instrument’s functionality, allowing system self-test and test programs to execute with no changes - eliminating the time and costs associated with re-verification.

- Flexibility to use both the legacy instrument and replacement instrument

- Ability to replicate “un-documented” behavior of a legacy instrument - which can be a key feature for performing accurate TPS execution since a TPS may use undocumented functions as a “feature” requiring the replacement instrument to behave the same.

FFF Replacement: GP1612 for HP8112

As shown in the chart below, the FFF solution when compared to all other alternatives, offers key advantages for those users looking to replace legacy instrumentation as well as preserving their investment in ATE and TPS.

Marvin Test Solutions' GP15xx and GP16xx instrumentation offers 100% form-fit-function drop in replacements for a broad range of GPIB pulse, arbitrary waveform and function generators that were manufactured by Wavetek and Hewlett-Packard.

|