Description

The TS-376 Optical Sight Sensor Test Station (OSSTS) is a state-of-the-art automatic test set (ATE) that provides test capabilities for optical InfraRed and Visible alignment, boresighting, acceptance testing, and periodic verification of target trackers for airborne and ground missile launchers such as the TOW2.

The TS-376 consists of two major subsystems: an Optical Subsystem and an Electronic Subsystem. The TS-376 is provided with a Test Program Set (TPS) for the TOW2 Optical Sight Sensor (OSS) commonly called the “daysight” or “daysight tracker,” and could be adapted to any number of Electro-Optical systems and/or subsystems requiring Visible and InfraRed target generation and tracking including the TOW Night Sight.

TOW2 Day-Sight Testing

The TS-376 provides OSS test capabilities for optical/IR alignment, boresighting, acceptance testing, and periodic verification of the TOW target tracker. Unlike previous OSS testers that were manual in nature and required extensive operator’s intervention and interpretation of the results, the TS- 376 is fully automated and performs digital measurements that do not require any intervention or interpretation.

Applications

The TS-376 provides a complete Depot testing solution for the TOW2 OSS. Additionally, it is suitable for the testing of a wide range of electro optical products including thermal imaging FLIR; day/night sensors; mobile, fixed thermal, CCTV, and Infrared surveillance systems and more.

Optical SubsystemThe optical subsystem of the TS-376 includes a 120” collimator based on a closed housing design that is not sensitive to ambient temperature changes, table deformation, or any other mechanical stress such as transportation. This eliminates the need for periodic alignment and calibration during operation or following transportation or installation. The TS-376 Optical Subsystem consists of the optical module, high temperature blackbody, chopper, visible light source, motorized target wheel, set of pin-hole targets, USAF Resolution Target, and Steering Mirror. All are fully computer programmable and controlled by the TS-376.

TS-376 Optical Subsystem

TS-376 Optical SubsystemThe design of the TS-376 is based on the PXI technology. PXI, PCI eXtensions for Instrumentation, is now being specified by most commercial and military customers as the platform of choice for field, intermediate, and depot level test equipment due to its rugged construction, high performance, and cost- effectiveness. The Test Program Set (TPS) for the TS-376 is a combination of hardware and software used to perform the functional tests of the OSS. The first part of the TPS is the mechanical holding fixture for the OSS unit under test (UUT). This fixture has been specifically designed and machined for mounting the TOW2 OSS. It uses a custom index plate mounting bracket with the same round mating connector found on the TOW2 Traversing Unit. Field replaceable and repairable cables connect the holding fixture to the ITA and the PXI instrumentation section. Another TPS verification cable provides a connection from the UUT connector on the holding fixture to the ITA. This ensures the test program can verify the integrity of the harness and connections to the UUT as required.

Test Program SetThe Test Program Set (TPS) for the TS-376 is a combination of hardware and software used to perform the functional tests of the OSS. The first part of the TPS is the mechanical holding fixture for the OSS unit under test (UUT). This fixture has been specifically designed and machined for mounting the TOW2 OSS. It uses a custom index plate mounting bracket with the same round mating connector found on the TOW2 Traversing Unit. Field replaceable and repairable cables connect the holding fixture to the ITA and then to the PXI instrumentation section. Another TPS verification cable provides a connection from the UUT connector on the holding fixture back to another round connector on the ITA. This ensures the test program can verify the integrity of the harness and connections to the UUT as required.

Performance

The TS-376 replaces the Hughes 400 station. It also provides significant improvements over this obsolete station in both the optical and electronic subsystems. It improves system reliability by eliminating reliance on weapon system end items, especially the analog or digital error detector cards. The automated architecture of the TS-376 reduces the TOW2 test time by 75% (30 minutes on the TS-376 vs. 2 hours on the Hughes 400).

Additionally, the TS-376 has OSS troubleshooting and repair capabilities, which were not provided with the Hughes 400 station. The scheduled maintenance and calibration requirements of the test system have been nearly eliminated with the exception of required periodic verifications.

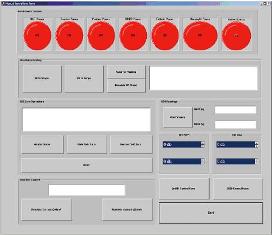

“Manual Operations Screen” for operator troubleshooting and optical alignments.

“Manual Operations Screen” for operator troubleshooting and optical alignments.| Marvin Test Solutions TS-376 | Hughes 400 |

|---|

| 120" Collimator | 120" Collimator |

| Enclosed optical system | Open air optical breadboard |

| COTS PXI instrumentation | GPIB and proprietary discrete-wire interfaces |

| COTS signal conditioning | Weapon end items removed from stock |

Order TS-376 and Related Products

To order call

1-888-837-8297

or order on-line via the form below. Prices are specified for

USA

destination orders. Prices are noted in USD.

Import duties, taxes, and charges are not included in the item price.